30-Nov-2014

I've been meaning to write about this one for quite some time, but it always slipped my mind, but here it is. Many a time during my 3D prints, the grub screw on the extruder motor's 9-tooth gear would come loose and slip causing the filament to stop feeding in. Tightening the grub screw too much would cause the 9-tooth gear to crack. I thought about this and decided that if I add a latch to the motor shaft, the grub screw could slot into it for added support.

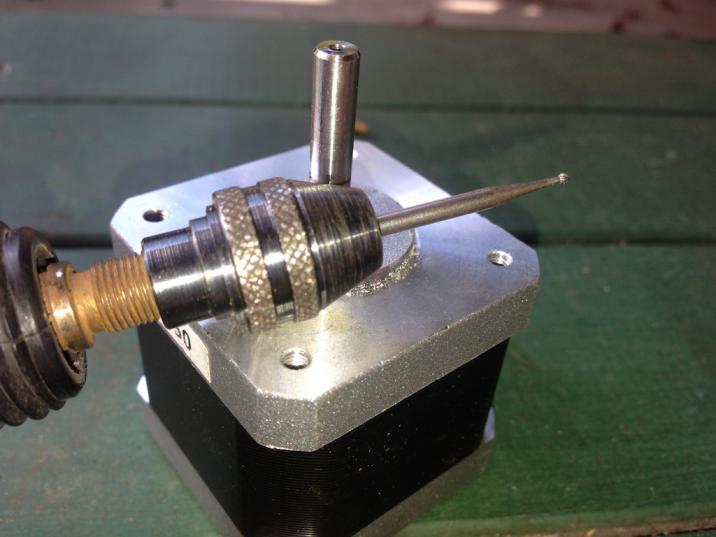

The idea is to use a Dremel tool to cut out a small cavity in the motor shaft that the grub screw could latch into. The cavity does not have to be that big, but it has to be wide enough to fit the entire grub screw head into it.

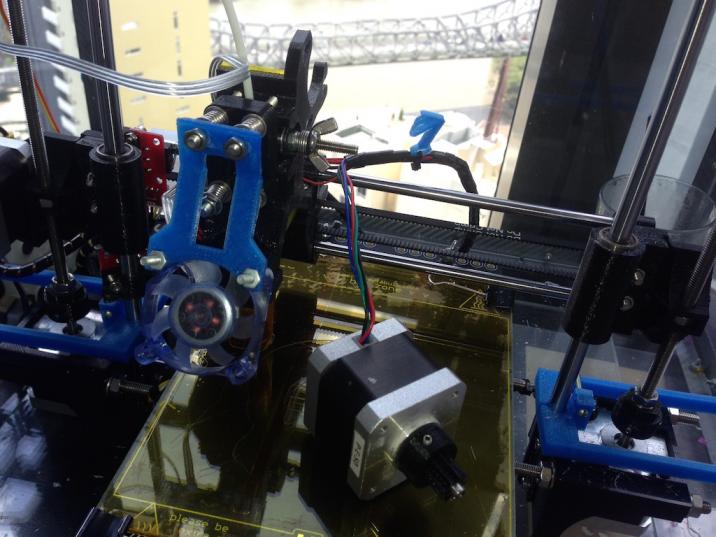

I began with removing the extruder motor and removing the 9-tooth gear.

This is the tip I used for the Dremel tool.

With the motor secured in a vice, I could start making the cavity.

It took a bit of time and came out a little rough, but it does work. I would have preferred a cleaner cut, but this is the best I could do by hand.

Now I don't have to over-tighten the grub screw to get a good grip on the motor shaft. The extruder works much better with this simple modification.

-i

A quick disclaimer...

Although I put in a great effort into researching all the topics I cover, mistakes can happen.

Use of any information from my blog posts should be at own risk and I do not hold any liability towards any information misuse or damages caused by following any of my posts.

All content and opinions expressed on this Blog are my own and do not represent the opinions of my employer (Oracle).

Use of any information contained in this blog post/article is subject to

this disclaimer.

Igor Kromin