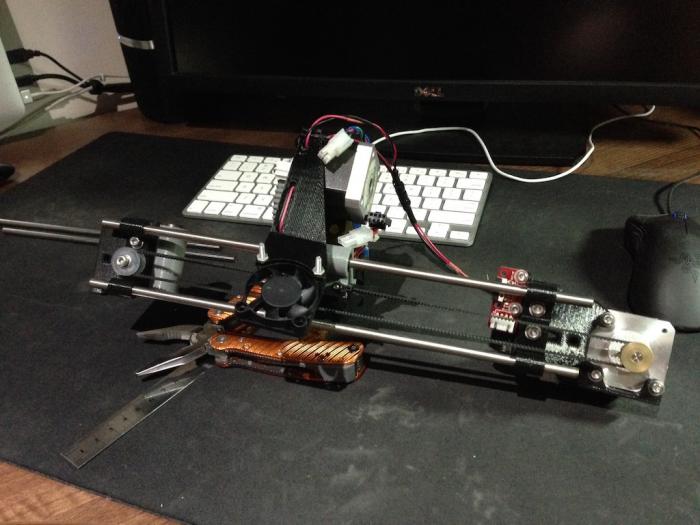

This is part three in the series of posts describing the project to rebuild the Portabee. This part will talk about the changes to the y-axis.

If you haven't read part two, you can find it here: http://www.igorkromin.net/index.php/2015/03/04/rebuilding-the-portabee-3d-printer-part-2/.

This part is relatively short compared to the others. The only changes to the y-axis were to use longer steel rods. I simply got 300mm rods in place of the original Portabee rods.

I had to disconnect the driver belt to extend the axis, that was a simple task. Luckily the existing belt had enough slack to make it usable with the new extended axis.

With the y-axis back together I could then start working on putting the whole printer back together. The y-axis had to go in to sit within the z-axis. Around this time I also attached the rest of the wiring connectors on the motors as I've previously just snipped the wiring off.

What followed next was a substantial amount of rewiring, this will be covered in the next post.

The fourth part is now posted, you can read it here: http://www.igorkromin.net/index.php/2015/03/06/rebuilding-the-portabee-3d-printer-part-4/.

-i